Introduction

Safety is paramount in any transportation system, and when it comes to the vast network of Indian Railways, ensuring the well-being of passengers is of utmost importance. With a rich history and millions of daily commuters, Indian Railways has consistently strived to enhance its safety measures.

In this article, we will delve into the safety initiatives taken by Indian Railways to protect its passengers and provide an insight into the advancements and challenges faced.

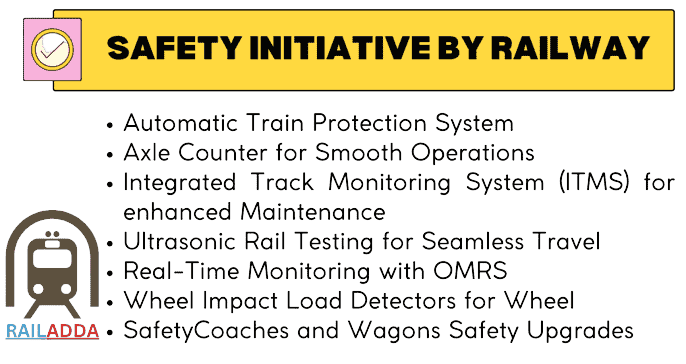

Safety Initiatives by Indian Railway

Indian Railways has initiated various safety measures to address modern challenges effectively to reduce the risk of accidents and to achieve smooth operation. Some of key initiative are as follows:

Automatic Train Protection System

In the past two years, Indian Railways has adopted several key safety technologies. The Automatic Train Protection (ATP) System, known as the Train Protection and Warning System (TPWS), has been implemented on 342 RKMs, including the Delhi-Agra Section, Chennai Suburban Section, and the Metro Railway in Kolkata. Additionally, the Train Collision Avoidance System (TCAS) is under trial on 250 RKMs of South Central Railway as a pilot project. These systems aim to further enhance railway safety.

Track Circuiting for Enhanced Safety

To ensure the safety of passengers, the Indian Railways has completed the track circuiting of stations at approximately 5989 locations as of May 31, 2018. This move has replaced manual track occupancy verification with electrical means, reducing the margin for human error.

Axle Counter for Smooth Operations

In a bid to streamline operations, the Axle Counter for Automatic Clearance of Block Section (BPAC) has been deployed across 5117 block sections as of May 31, 2018. This advancement ensures the complete arrival of trains without manual intervention before granting line clearance to the next train, thereby reducing human intervention.

Level Crossing Gates Interlocking for Safety

Safety at level crossings is of paramount importance. The Indian Railways has interlocked level crossing gates with signals at 11057 locations as of May 31, 2018, to prevent accidents and enhance safety for commuters.

Integrated Track Monitoring System (ITMS)

The Integrated Track Monitoring System (ITMS) is capable of recording identifiable track component defects, allowing for proactive maintenance and safer railway operations.

Ultrasonic Rail Testing for Seamless Travel

The introduction of Self Propelled Ultrasonic Rail Testing (SPURT) cars has revolutionised rail flaw detection. These cars are equipped to detect internal flaws in rails, ensuring the safety and reliability of railway tracks.

Monitoring Track Defects with Axle Box Level Accelerometers

Axle box level accelerometers have been deployed to monitor track defects daily, enabling quick response to any potential safety issues.

Electrical/Electronic Interlocking System:

To eliminate human error, the Indian Railways has implemented Electrical/Electronic Interlocking Systems with centralised operation of points and signals at 5781 stations as of May 31, 2018.

Crew Voice/Video Recording for Analysis

For post-failure event analysis, locomotives equipped with Crew Voice/Video recording systems have been commissioned. These systems ensure effective and tamper-proof video and voice recording of the locomotive cab.

Real-Time Monitoring with OMRS

The Online Monitoring of Rolling Stock (OMRS) system is a game-changer in safety monitoring. It detects defective bearings and wheel flats in real-time, allowing for immediate corrective action.

Wheel Impact Load Detectors for Wheel Safety

Fifteen Wheel Impact Load Detectors (WILDs) are operational in Indian Railways. These detectors automatically identify defective wheels by measuring their impact on the track, contributing to enhanced safety.

Welding Quality Improvements:

Mechanised preheating, three-piece prefabricated molds, auto tapping thimbles, and single short crucibles provided.

Ultrasonic Flaw Detection (USFD):

New specifications issued by Research Design & Standards Organisation (RDSO). Features location tagging, time stamping of recordings, and improved scan (B-scan) capability.

Advanced Safety Monitoring:

Continued use of Integrated Track Monitoring Systems (ITMS) and Self-Propelled Ultrasonic Rail Testing (SPURT) cars.

Daily Track Health Monitoring:

Project to deploy Axle Box Level Accelerometers on Rajdhani type trains on Group-A routes. Ensures daily monitoring of track defects on covered routes.

Coaches and Wagons Safety Upgrades:

Modified Centre Buffer couplers, Bogie Mounted Air Brake Systems (BMBS), improved suspension design, and Automatic fire and smoke detection systems in coaches. Enhancing overall safety standards.